Projects > Automated Mast Sorting Device

Automated Mast Sorting Device

August 2018 - May 2019

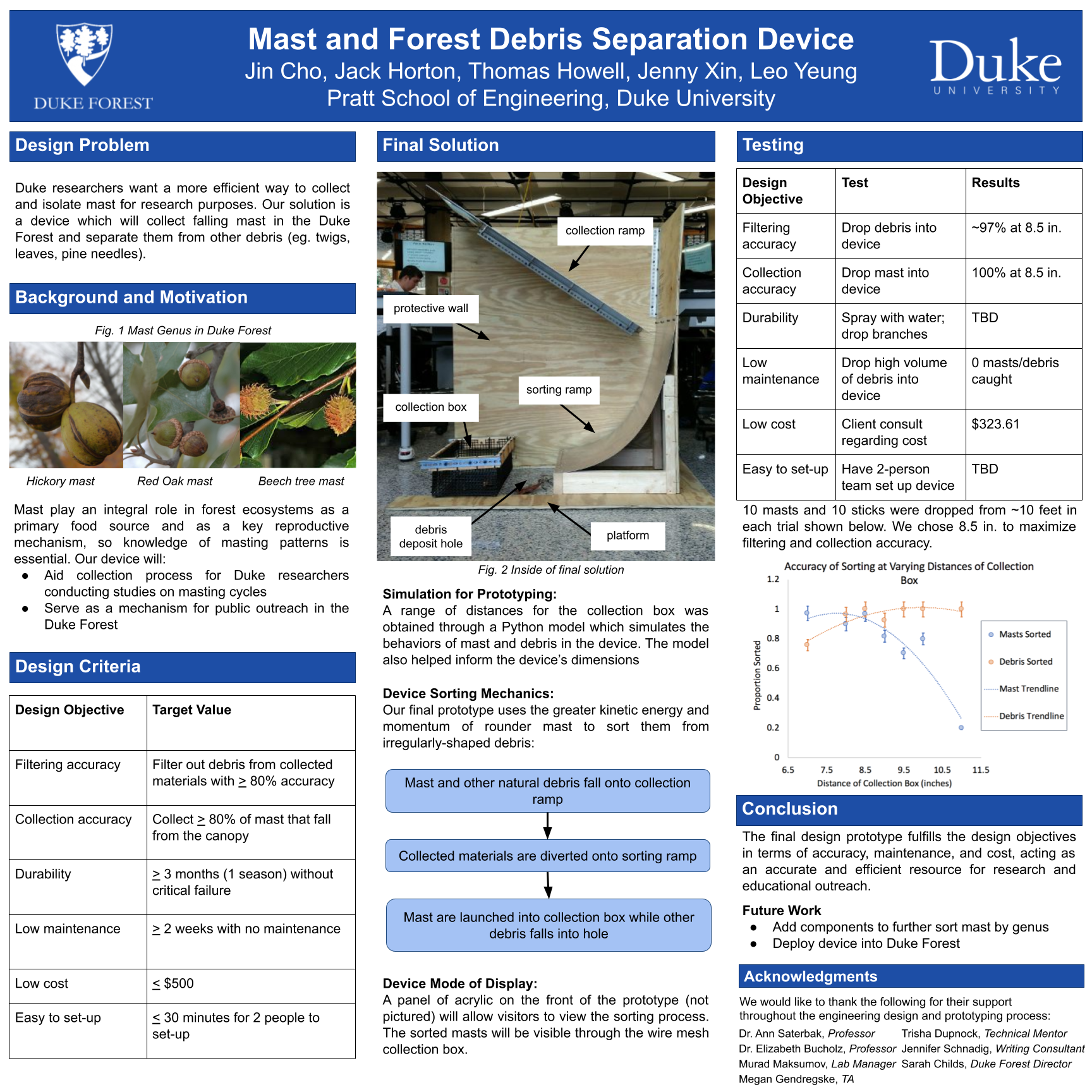

Figure 1: Final design for mast sorting device.

Background

Figure 1: Final design for mast sorting device.

Background

At the base of every forest ecosystem are mast, or the

fruits of trees and shrubs, which includes acorns, hickory

nuts, and beech nuts. Mast play several

fundamental roles in ecology, from sustaining animal

populations to influencing reproduction patterns.

Variations in masting cycles can cause

fluctuations in animal populations and can provide

important information relating to weather patterns and

other environmental factors such as climate change.

One of the main goals of the Duke Forest is to study

masting cycles in order to better understand forest trends

and to educate the public about the environment. To

conduct this research, the Duke Forest staff collects

thousands of mast to study. The original method of

mast collection employed by Duke Forest

researchers was a simple laundry basket with a net on

top to separate out sticks and leaves. However, it

takes Duke Forest researchers a significant amount of

time to sort the collected mast by genus and to

remove all other organic debris by hand for testing

after collection. Thus, the Duke Forest researchers

sought a design which would ultimately remove organic

debris from the collected mast as well as sort

the mast by genus. In the Fall of 2018, this design

project was assigned to a group of first-year Duke engineering students in

partnership with Duke University’s First Year Design

experience to give practical, real-world applicable

tasks to incoming freshman engineers. The project was

then continued in the Spring of 2019 by a smaller

team. The final design for the mast collector is shown

in Figure 1.

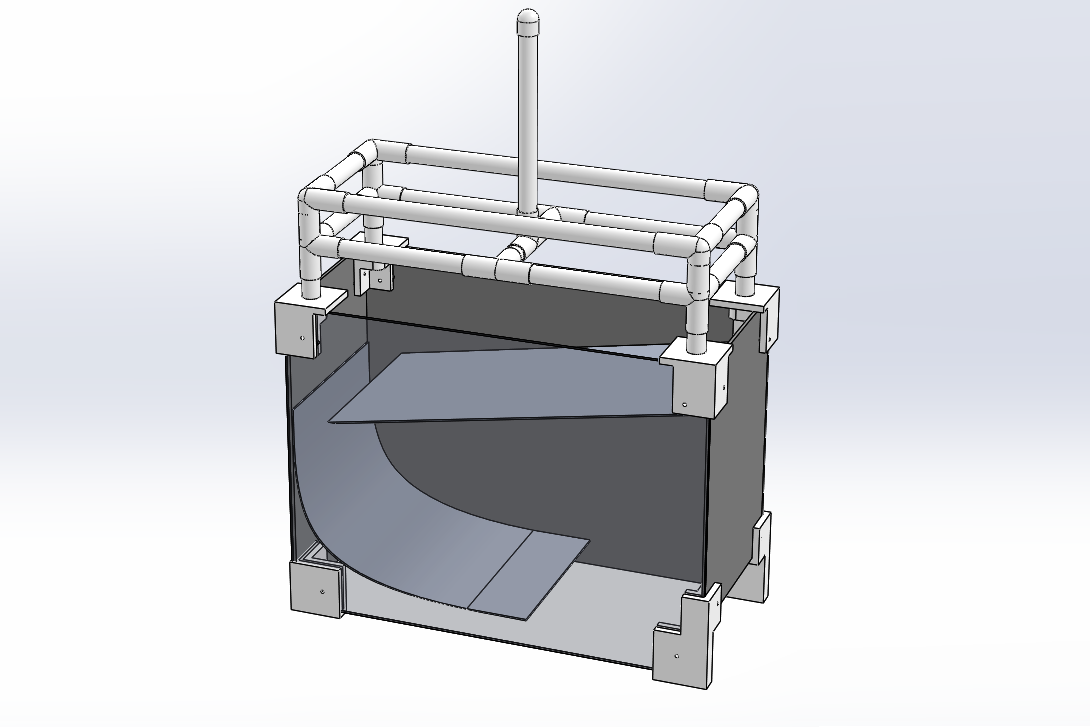

Figure 2: Final prototype of mast collector.

Key Design Features

Figure 2: Final prototype of mast collector.

Key Design Features

Before mast can be sorted by genus, they first need to be isolated from other natural debris. In pursuit of

this goal, the device was designed with a clear focus on the efficacy of the collector: accurately filtering

sticks, leaves, and other debris while still collecting all of the mast. Other factors were also considered,

such as the cost, weight, and durability of the collector. The final mast collector design is

split into two parts: an upper collector and a lower collector.

The as-built prototype is shown in Figure 2.

Upper Collector

To prevent larger branches from falling into the device and clogging up the lower

collector, the upper filter was created using a PVC

frame and a flexible mesh net. The goal of

the upper filter is to block out larger debris that

could possibly impede the collector’s function by

blocking the metal ramp while still allowing mast to

pass through, allowing for the collector to operate

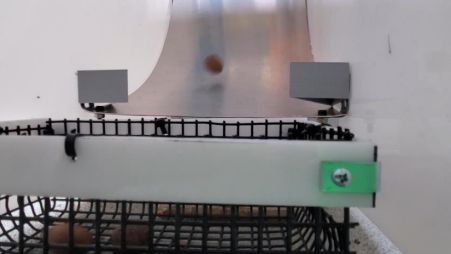

for a longer time before requiring maintenance. A closer

look at the upper collector is presented in Figure 3.

Lower Collector

The lower collector, shown in Figure 4, is made out of a strong and

lightweight polycarbonate material and held

together by lightweight 3D printed plastic joints

and metal L-brackets, which allows for ease of

transportation and maneuverability, along with

making the entire design modular. The two ramps are

made from aluminum sheet metal. This

component of the device separates mast from

other tree debris using their kinetic energies.

Since mast are more spherical in shape, they are

able to roll down the ramp while other debris

slides at a much slower speed. This difference

in speed allows the mast to launch over the gap

between the ramp and the collection bin while sticks and

leaves fail to clear the gap. The unwanted debris

then slides into the gap and out of the bottom of the

mast collector onto the forest floor.

Figure 3: Upper collector.

Figure 3: Upper collector.

Figure 4: Lower collector.

Figure 4: Lower collector.

Original Design and Poster Presentation

At the end of the Fall 2018 semester, the team presented the design and prototype at a poster session. This poster features the prototype constructed before the spring redesign, so it is made from wood instead of polycarbonate. It is also considerably larger than the redesigned iteration and lacks the upper collector portion.