Pressure Vessel

October 2021 - November 2021

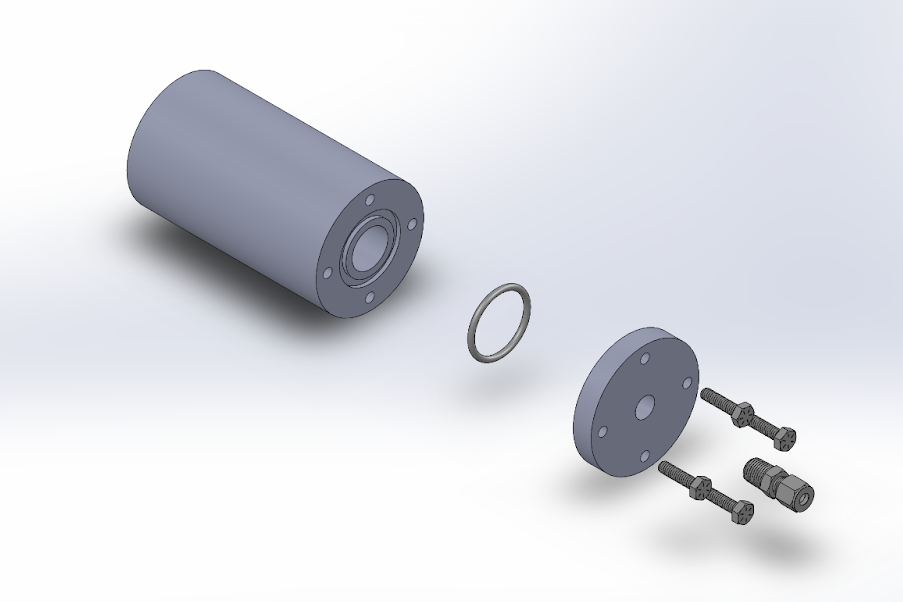

Figure 1: Exploded view of pressure vessel.

Background and Key Design Features

Figure 1: Exploded view of pressure vessel.

Background and Key Design Features

In a team of 4 students, I designed, machined, and tested

a gas pressure vessel to be used in a laboratory environment.

The vessel was required to hold 50-60cc of fluid at

a pressure of 750psi and to cost no more than $100

in parts from McMaster Carr. An exploded view of the

final design is shown to the left in Figrue 1. The

vessel is made from 1215 steel and is 5.76” in length

and 3” in outside diameter. To prevent fluid leakage,

the team selected an O-ring face seal between the cap

and the body of the vessel with 4 hex head screws to

secure the two components together. A face seal was

chosen over a plug due to ease of machining. The cap

is complete with a 1/4 NPT pipe fitting through which

fluid can enter and exit the vessel.

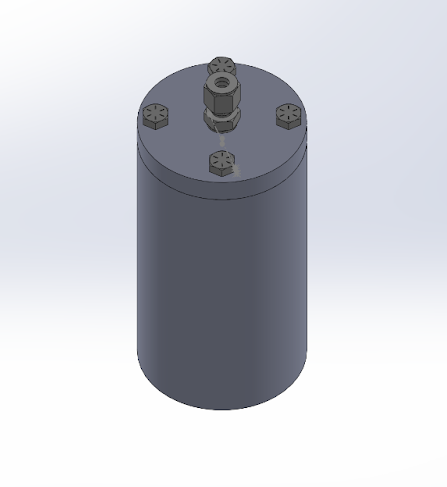

Figure 2: Assembled view of pressure vessel.

The final cost

of the machined pressure vessel is $57.48, which is

well below budget. See Table 1 for a costed bill of

materials. The minimum factor of safety (FOS)

for the design was computed to be 2 due to the fact that the selected

O-ring is rated for a maximum fluid pressure of 1500psi.

After assembly, the pressure vessel was successfully tested up

to 1000psi. A view of the assembled pressure vessel is shown

in Figure 2.

Figure 2: Assembled view of pressure vessel.

The final cost

of the machined pressure vessel is $57.48, which is

well below budget. See Table 1 for a costed bill of

materials. The minimum factor of safety (FOS)

for the design was computed to be 2 due to the fact that the selected

O-ring is rated for a maximum fluid pressure of 1500psi.

After assembly, the pressure vessel was successfully tested up

to 1000psi. A view of the assembled pressure vessel is shown

in Figure 2.

Table 1: Costed Bill of Materials

| Part Name | Part Number | Quantity | Cost per unit |

|---|---|---|---|

| 1215 Carbon Steel - 3” diameter, 6” long | 4416T29 | 1 | $44.79 |

| Oil Resistant Buna-N O-Ring - ⅛” Fractional Width, 221 | 9452K42 | 1 | $0.13 |

| Zinc Yellow-Chromate Plated Hex Head Screw, Grade 8 Steel, 1/4"-20 Thread Size, 1" Long - Washers Included | 92620A542 | 4 | $0.14 |

| Swagelok B-400-1-4 Fitting | N/A | 1 | $3.70 |

| Total: | $57.48 | ||